- 1

- 2

- Source: Process engineering

- Source: Process (engineering)

- Proses bisnis

- Rekayasa ulang proses bisnis

- Injeksi molding

- Internet Engineering Task Force

- Agile Unified Process

- Unified Process

- Personal software process

- ENPPI

- Team software process

- Sekolah Teknik Elektro dan Informatika Institut Teknologi Bandung

- Process engineering

- Process (engineering)

- Engineering design process

- Mixing (process engineering)

- Sales process engineering

- Systems engineering

- Business process re-engineering

- Wet process engineering

- Software development process

- Industrial engineering

Attack (2022)

Jurassic World: Fallen Kingdom (2018)

Underwater (2020)

Mobile Suit Gundam SEED FREEDOM (2024)

Aporia (2023)

The Amazing Spider-Man (2012)

Tokyo Gore Police (2008)

Black Sheep (2007)

Alien Resurrection (1997)

The Martian (2015)

Pabrik Gula (2025)

The Phantom of the Open (2022)

Love in the Big City (2024)

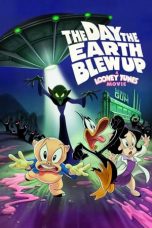

The Day the Earth Blew Up: A Looney Tunes Movie (2024)

Artikel: Process engineering GudangMovies21 Rebahinxxi

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Their work involves analyzing the chemical makeup of various ingredients and determining how they might react with one another. A process engineer can specialize in a number of areas, including the following:

Agriculture processing

Food and dairy production

Beer and whiskey production

Cosmetics production

Pharmaceutical production

Petrochemical manufacturing

Mineral processing

Printed circuit board production

Overview

Process engineering involves the utilization of multiple tools and methods. Depending on the exact nature of the system, processes need to be simulated and modeled using mathematics and computer science. Processes where phase change and phase equilibria are relevant require analysis using the principles and laws of thermodynamics to quantify changes in energy and efficiency. In contrast, processes that focus on the flow of material and energy as they approach equilibria are best analyzed using the disciplines of fluid mechanics and transport phenomena. Disciplines within the field of mechanics need to be applied in the presence of fluids or porous and dispersed media. Materials engineering principles also need to be applied, when relevant.

Manufacturing in the field of process engineering involves an implementation of process synthesis steps. Regardless of the exact tools required, process engineering is then formatted through the use of a process flow diagram (PFD) where material flow paths, storage equipment (such as tanks and silos), transformations (such as distillation columns, receiver/head tanks, mixing, separations, pumping, etc.) and flowrates are specified, as well as a list of all pipes and conveyors and their contents, material properties such as density, viscosity, particle-size distribution, flowrates, pressures, temperatures, and materials of construction for the piping and unit operations.

The process flow diagram is then used to develop a piping and instrumentation diagram (P&ID) which graphically displays the actual process occurring. P&ID are meant to be more complex and specific than a PFD. They represent a less muddled approach to the design. The P&ID is then used as a basis of design for developing the "system operation guide" or "functional design specification" which outlines the operation of the process. It guides the process through operation of machinery, safety in design, programming and effective communication between engineers.

From the P&ID, a proposed layout (general arrangement) of the process can be shown from an overhead view (plot plan) and a side view (elevation), and other engineering disciplines are involved such as civil engineers for site work (earth moving), foundation design, concrete slab design work, structural steel to support the equipment, etc. All previous work is directed toward defining the scope of the project, then developing a cost estimate to get the design installed, and a schedule to communicate the timing needs for engineering, procurement, fabrication, installation, commissioning, startup, and ongoing production of the process.

Depending on needed accuracy of the cost estimate and schedule that is required, several iterations of designs are generally provided to customers or stakeholders who feed back their requirements. The process engineer incorporates these additional instructions (scope revisions) into the overall design and additional cost estimates, and schedules are developed for funding approval. Following funding approval, the project is executed via project management.

Principal areas of focus in process engineering

Process engineering activities can be divided into the following disciplines:

Process design: synthesis of energy recovery networks, synthesis of distillation systems (azeotropic), synthesis of reactor networks, hierarchical decomposition flowsheets, superstructure optimization, design multiproduct batch plants, design of the production reactors for the production of plutonium, design of nuclear submarines.

Process control: model predictive control, controllability measures, robust control, nonlinear control, statistical process control, process monitoring, thermodynamics-based control, denoted by three essential items, a collection of measurements, method of taking measurements, and a system of controlling the desired measurement.

Process operations: scheduling process networks, multiperiod planning and optimization, data reconciliation, real-time optimization, flexibility measures, fault diagnosis.

Supporting tools: sequential modular simulation, equation-based process simulation, AI/expert systems, large-scale nonlinear programming (NLP), optimization of differential algebraic equations (DAEs), mixed-integer nonlinear programming (MINLP), global optimization, optimization under uncertainty, and quality function deployment (QFD).

Process Economics: This includes using simulation software such as ASPEN, Super-Pro to find out the break even point, net present value, marginal sales, marginal cost, return on investment of the industrial plant after the analysis of the heat and mass transfer of the plant.

Process Data Analytics: Applying data analytics and machine learning methods for process manufacturing problems.

History of process engineering

Various chemical techniques have been used in industrial processes since time immemorial. However, it wasn't until the advent of thermodynamics and the law of conservation of mass in the 1780s that process engineering was properly developed and implemented as its own discipline. The set of knowledge that is now known as process engineering was then forged out of trial and error throughout the industrial revolution.

The term process, as it relates to industry and production, dates back to the 18th century. During this time period, demands for various products began to drastically increase, and process engineers were required to optimize the process in which these products were created.

By 1980, the concept of process engineering emerged from the fact that chemical engineering techniques and practices were being used in a variety of industries. By this time, process engineering had been defined as "the set of knowledge necessary to design, analyze, develop, construct, and operate, in an optimal way, the processes in which the material changes". By the end of the 20th century, process engineering had expanded from chemical engineering-based technologies to other applications, including metallurgical engineering, agricultural engineering, and product engineering.

See also

References

External links

Advanced Process Engineering at Cranfield University (Cranfield, UK)

Sargent Centre for Process Systems Engineering (Imperial)

Process Systems Engineering at Cornell University (Ithaca, New York)

Department of Process Engineering at Stellenbosch University

Process Research and Intelligent Systems Modeling (PRISM) group at BYU

Process Systems Engineering at CMU

Process Systems Engineering Laboratory at RWTH Aachen

The Process Systems Engineering Laboratory (MIT)

Process Engineering Consulting at Canada

Artikel: Process (engineering) GudangMovies21 Rebahinxxi

In engineering, a process is a series of interrelated tasks that, together, transform inputs into a given output. These tasks may be carried out by people, nature or machines using various resources; an engineering process must be considered in the context of the agents carrying out the tasks and the resource attributes involved. Systems engineering normative documents and those related to Maturity Models are typically based on processes, for example, systems engineering processes of the EIA-632 and processes involved in the Capability Maturity Model Integration (CMMI) institutionalization and improvement approach. Constraints imposed on the tasks and resources required to implement them are essential for executing the tasks mentioned.

Semiconductor industry

Semiconductor process engineers face the unique challenge of transforming raw materials into high-tech devices. Common semiconductor devices include Integrated Circuits (ICs), Light-Emitting Diodes (LEDs), solar cells, and solid-state lasers. To produce these and other semiconductor devices, semiconductor process engineers rely heavily on interconnected physical and chemical processes.

A prominent example of these combined processes is the use of ultra-violet photolithography which is then followed by wet etching, the process of creating an IC pattern that is transferred onto an organic coating and etched onto the underlying semiconductor chip. Other examples include the ion implantation of dopant species to tailor the electrical properties of a semiconductor chip and the electrochemical deposition of metallic interconnects (e.g. electroplating). Process Engineers are generally involved in the development, scaling, and quality control of new semiconductor processes from lab bench to manufacturing floor.

Chemical engineering

A chemical process is a series of unit operations used to produce a material in large quantities.

In the chemical industry, chemical engineers will use the following to define or illustrate a process:

Process flow diagram (PFD)

Piping and instrumentation diagram (P&ID)

Simplified process description

Detailed process description

Project management

Process simulation

CPRET

The Association Française d'Ingénierie Système has developed a process definition dedicated to Systems engineering (SE), but open to all domains.

The CPRET representation integrates the process Mission and Environment in order to offer an external standpoint. Several models may correspond to a single definition depending on the language used (UML or another language).

Note: process definition and modeling are interdependent notions but different the one from the other.

Process

A process is a set of transformations of input elements into products: respecting constraints,

requiring resources,

meeting a defined mission, corresponding to a specific purpose adapted to a given environment.

Environment

Natural conditions and external factors impacting a process.

Mission

Purpose of the process tailored to a given environment.

This definition requires a process description to include the Constraints, Products, Resources, Input Elements and Transformations. This leads to the CPRET acronym to be used as name and mnemonic for this definition.

Constraints

Imposed conditions, rules or regulations.

Products

All whatever is generated by transformations. The products can be of the desired or not desired type (e.g., the software system and bugs, the defined products and waste).

Resources

Human resources, energy, time and other means required to carry out the transformations.

Elements as inputs

Elements submitted to transformations for producing the products.

Transformations

Operations organized according to a logic aimed at optimizing the attainment of specific products from the input elements, with the allocated resources and on compliance with the imposed constraints.

= CPRET through examples

=The purpose of the following examples is to illustrate the definitions with concrete cases. These examples come from the Engineering field but also from other fields to show that the CPRET definition of processes is not limited to the System Engineering context.

Examples of processes

An engineering (EIA-632, ISO/IEC 15288, etc.)

A concert

A polling campaign

A certification

Examples of environment

Various levels of maturity, technicality, equipment

An audience

A political system

Practices

Examples of mission

Supply better quality products

Satisfy the public, critics

Have candidates elected

Obtain the desired approval

Examples of constraints

Imposed technologies

Correct acoustics

Speaking times

A reference model (ISO, CMMI, etc.)

Examples of products

A mobile telephone network

A show

Vote results

A quality label

Examples of resources

Development teams

An orchestra and its instruments

An organization

An assessment team

Examples of elements as inputs

Specifications

Scores

Candidates

A company and its practices

Examples of transformations

Define an architecture

Play the scores

Make people vote for a candidate

Audit the organization

Conclusions

The CPRET formalized definition systematically addresses the input Elements, Transformations, and Products but also the other essential components of a Process, namely the Constraints and Resources. Among the resources, note the specificity of the Resource-Time component which passes inexorably and irreversibly, with problems of synchronization and sequencing.

This definition states that environment is an external factor which cannot be avoided: as a matter of fact, a process is always interdependent with other phenomena including other processes.

References

Bibliography

Kata Kunci Pencarian:

Artikel Terkait "process engineering"

Process engineering - Wikipedia

Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Their work involves analyzing the chemical …

Process Engineering – Everything You Need To Know!

11 Jan 2018 · In this article, we’ll take a deep look at process engineering, and discuss everything you need to know about this field. From the basics about what process engineering is, to …

What Does a Process Engineer Do? (With Job Requirements)

27 Jun 2024 · A process engineer works in a manufacturing facility, factory or plant and uses equipment to transform raw materials into a final product. These engineers use their …

What is a Process Engineer and How Can You Become One? - GetReskilled

A Process Engineer designs, implements and optimises chemical & biochemical processes, especially continuous flow ones on an industrial scale

What is Process Engineering and What Do Process Engineers Do?

Process engineering is the understanding and application of the basic principles and laws of nature that enable humans to transform raw materials and energy into products useful to …

What is Process Engineering? A Complete Guide - Lean Outside …

05 Sep 2022 · Key Takeaways ️ The role of a process engineer is to design, analyze, and optimize processes by minimizing both time and material waste. ️ Continuous improvement …

What is process engineering and what is a process engineer?

22 Jun 2024 · Process engineering is the process of researching and using raw materials to create valuable everyday products. For example, a process engineer during a given workday …

What Does a Process Engineer Do? Role, Responsibilities, Impact

08 Nov 2024 · A Process Engineer in Manufacturing is a specialist responsible for the development, optimization and control of technological processes. The main purpose of his …

What Is A Process Engineer? An In-Depth Guide To This Crucial …

24 Jan 2023 · Process engineers play a crucial role in modern manufacturing and industrial sectors, contributing to the development of new products and the enhancement of existing …

What is a Process Engineer? - Teal HQ

Process Engineers play a pivotal role in the design, implementation, and optimization of industrial processes, ensuring efficiency, quality, and safety. They apply principles of engineering, …